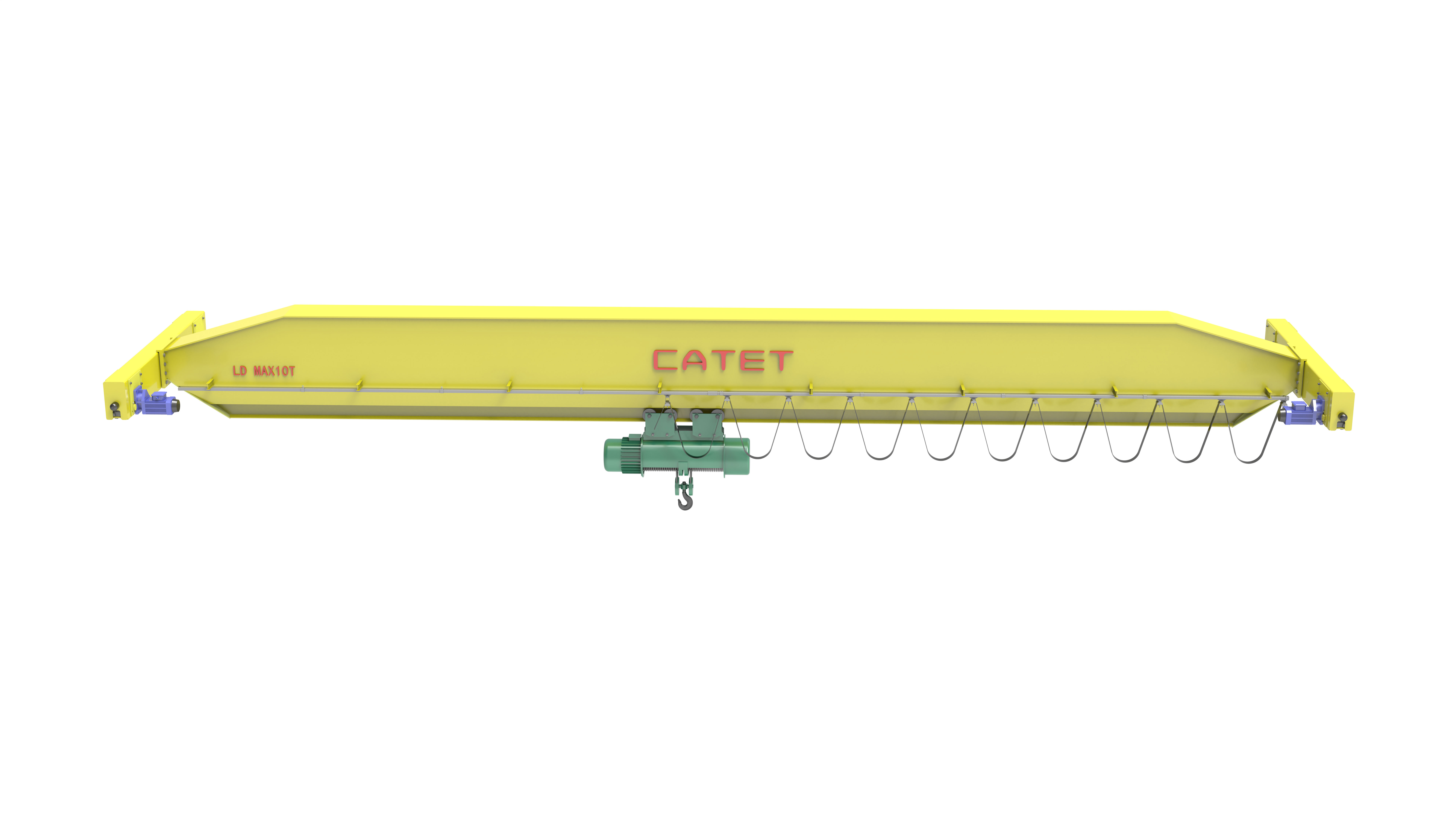

Lifting equipment is generally used to lift heavy goods and is widely used in the machinery industry. To save costs, enterprises often make single-girder cranes work continuously and frequently, causing severe wear on the mechanical transmission components. Moreover, they do not pay attention to maintenance, which makes the service life of the equipment fail to reach the required years. Today, I will introduce some maintenance tips for single-girder cranes to you.

1. Check the temperature of the motor housing and bearing components of the single-girder crane, and inspect the noise and vibration of the motor.

1. Check the temperature of the motor housing and bearing components of the single-girder crane, and inspect the noise and vibration of the motor.

2.When the crane starts frequently, due to the low rotational speed, the ventilation and heat dissipation capacity decreases, the current is large, and the motor temperature rises rapidly. It should be noted that the temperature rise of the motor must not exceed the upper limit specified in the user manual, and the brake should be adjusted in accordance with the requirements of the motor user manual.

3. The crane is frequently used, has good sealing conditions and operates in a favorable environment. The lubricating oil in the crane gearbox needs to be replaced every six months. When the working environment is harsh, the lubricating oil needs to be replaced every quarter. If water is found in the fuel tank or there is always foam on the oil surface and the oil has deteriorated, the oil must be replaced immediately. The oil replacement should be carried out strictly in accordance with the instructions in the operation to avoid oil mixing.

4. The daily maintenance of the reducer can be carried out in accordance with the operation manual of the manufacturer. The anchor bolts of the reducer should be frequently inspected and the connection should not be loose