Technical parameters of LX electric single beam bridge crane | ||

| Rated Load | T | 1~10 |

| Work Level | A3~A5 | |

| Equipment Span | S(m) | 3~20 |

| Lifting Height | m | 3~30 |

| Product Certification | ISO, CE | |

| Design Standard | GB3811 | |

Introduction to European double-beam bridge crane

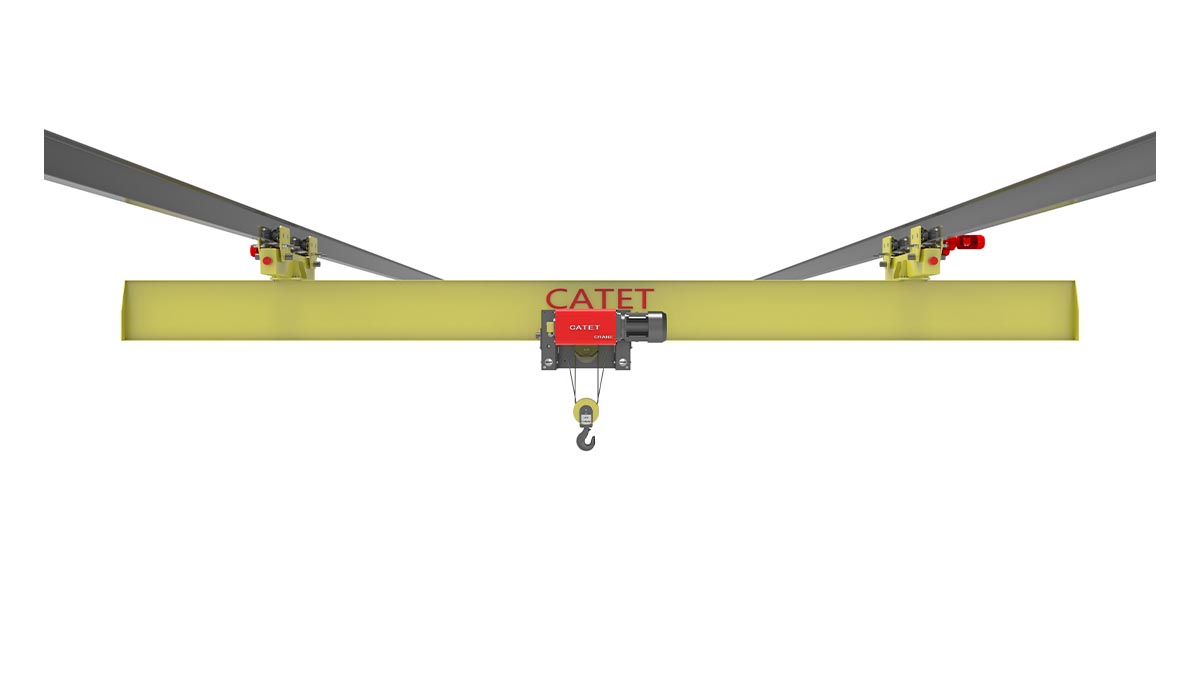

LX series electric single-beam suspension bridge crane adopts European standard modular design, compact structure, light weight, low noise, all operating mechanisms of the whole machine adopt frequency conversion control, energy saving, environmental protection, maintenance-free, low noise and other advantages, it is a new type of suspension bridge crane with higher working level (optional explosion-proof type).

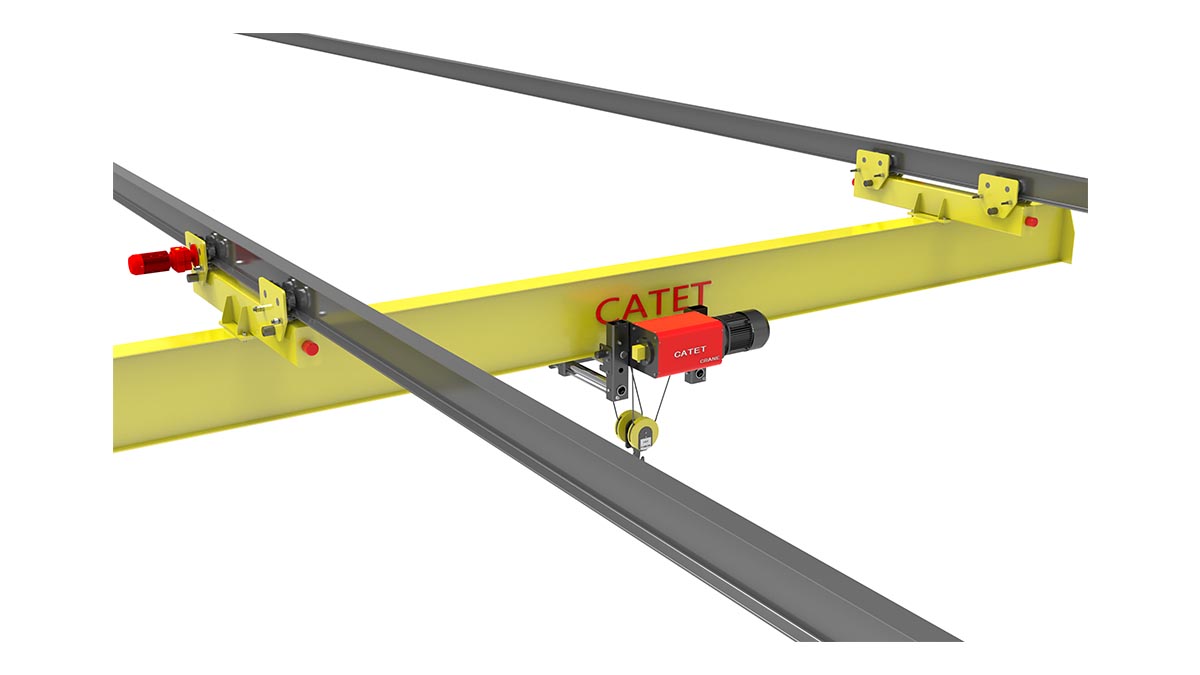

Electric single-beam suspension bridge crane composition: bridge, suspension end beam, lifting mechanism (electric hoist, chain hoist can be selected), trolley running mechanism, electrical system.

Advantages of LX single-beam suspension bridge crane

■ Adopting European technology, the whole machine adopts suspension modular design

■ Light weight, small wheel pressure, safe and reliable, green concept leads innovation, saves space and energy.

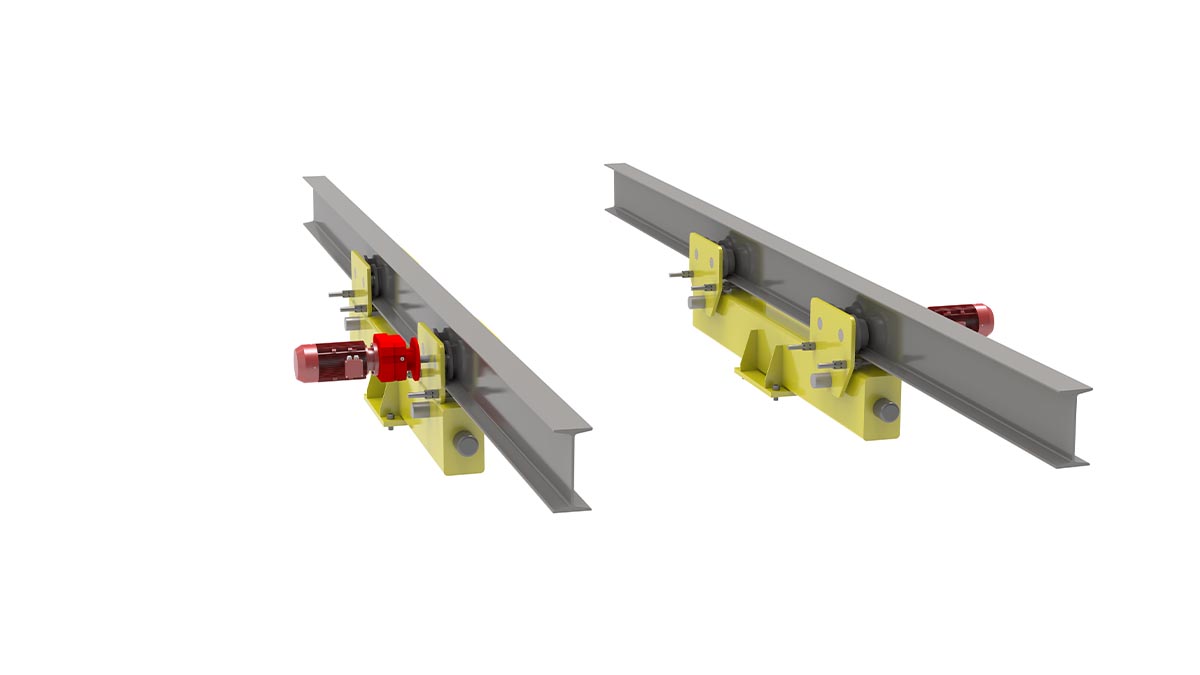

■ The whole machine is controlled by full frequency conversion control, and the walking mechanism and lifting mechanism adopt three-in-one motor reducer, which runs smoothly, safely and reliably.

Main Beam

■ European design: made of Q235B or Q355E steel, the design meets European standards, compact structure, light weight, easy to work in limited space.

■ Suspended bridge: According to the different needs of the workshop, the main beam design adopts a suspended style, which does not occupy the ground space and is suitable for occasions in special working areas.

Electric Hoist

■ Equipped with a fully variable frequency European electric hoist, the lifting process is smoother, safer, and improves work efficiency.

■ The electric hoist adopts variable frequency speed regulation: 2 speeds can be designed to achieve fast and slow speeds.

Operation system:

■ The three-in-one variable frequency brake motor is used to ensure the smooth operation of the crane, reduce vibration, and increase the life of the equipment.■ It has the characteristics of high hardness, strong load-bearing capacity, wear resistance and long service life.

Safety protection device:

■ Overload protection: The equipment is equipped with an overload protection device. Once the load exceeds the limit, the system automatically stops working to prevent accidents

■ Limit switch: Used to control the lifting height of the equipment to prevent the equipment from exceeding the safe operating range and preventing top impact.

■ Anti-hook drop device: Prevent the goods from falling off due to loose or broken hooks, and ensure the safety of the working environment.

■ Electrical overload protection: Ensure the normal operation of the electrical system and avoid equipment damage due to current overload.

■ Lifting capacity: 1~10 tons (different lifting capacities can be customized)

■ Lifting height: 3-30 meters (can be customized according to actual needs).

■ Lifting speed: 0-5 meters/minute. Frequency conversion speed regulation

■ Operating speed: 2~20 meters/minute. Frequency conversion speed regulation

■ Power supply voltage: 220V-600V, 50/60Hz

■ Protection level: IP54 and above, suitable for a variety of industrial environments.

■ Working environment temperature: -10℃ to +40℃.

Application scenarios

■ Warehousing and logistics: suitable for warehouses, logistics centers and other environments that are suitable for efficient and fast handling of goods.

■ Manufacturing: used for material handling in production workshops, mechanical processing, and assembly lines.

■ Steel and metallurgy: widely used in heavy industrial places such as steel mills and smelters, can carry heavy loads, and meet the high-intensity requirements of production.

■ Chemical, food and other industries: suitable for industries that require frequent use and require efficient and stable operation, such as fertilizer plants, food processing plants, etc.

Applicable standards

■ European standard: Meets the quality standards of European CE certification, ensuring the international consistency of product quality, performance and safety.

■ ISO 9001 certification: Meets international quality management system standards to ensure product consistency and reliability.