Technical Parameter of MATE-QD A5-A7 Double Beam Overhead Crane | ||

| Rated Load | T | 3~500 |

| Work Level | A3~A7 | |

| Equipment Span | S(m) | 5~50 |

| Lifting Height | m | 6~50 |

| Product Certification | ISO, CE | |

| Design Standard | GB3811 | |

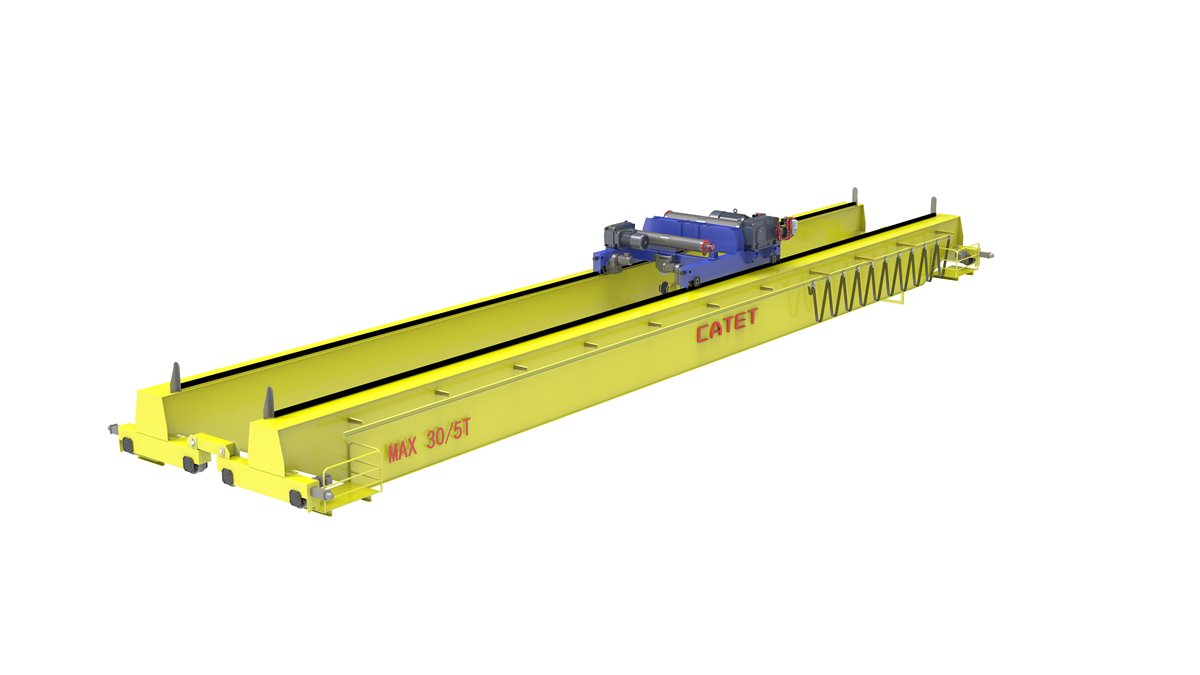

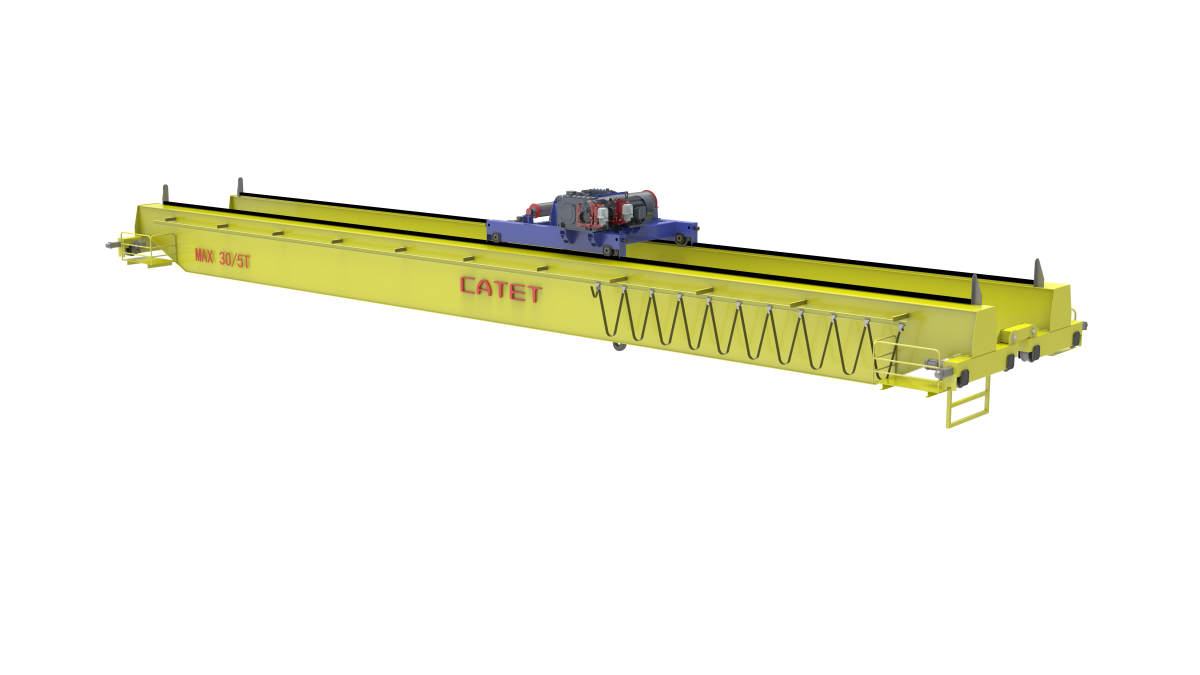

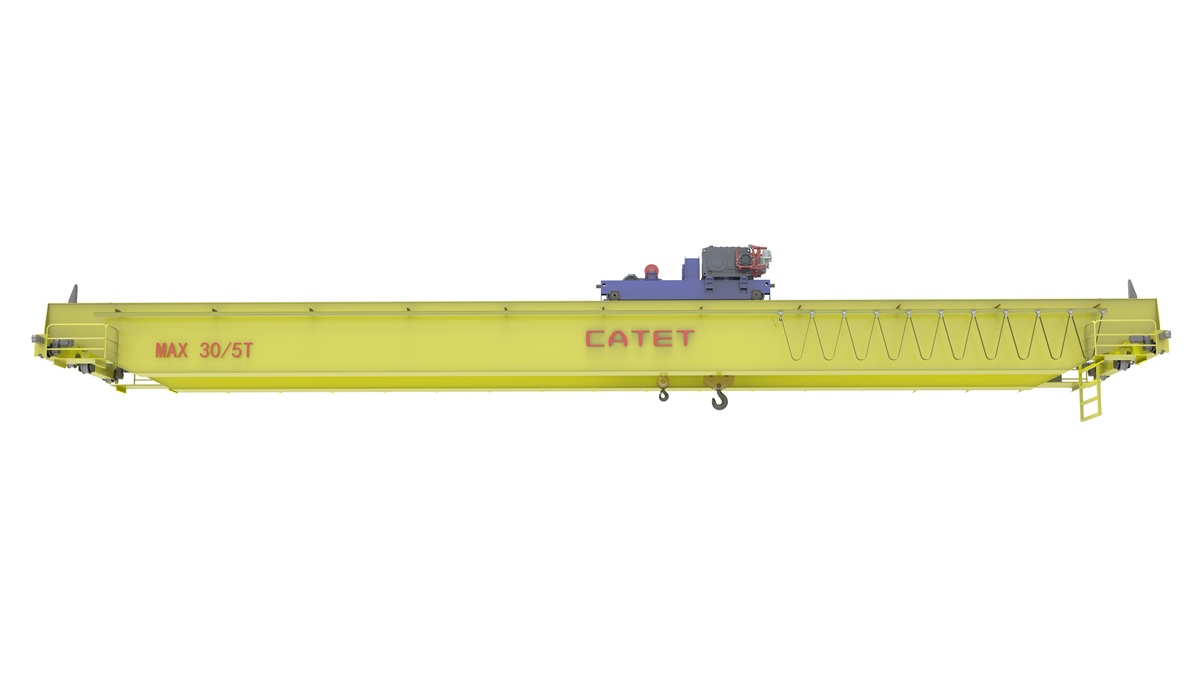

MATE-QD series European standard electric double-beam bridge crane is a new type of bridge crane that is upgraded from traditional cranes. The whole machine adopts European standard modular design, compact structure, light weight, low noise, and frequency conversion control, energy saving, environmental protection, maintenance-free, and is a new type of bridge crane with a higher working level (optional explosion-proof type).

Electric double-beam bridge crane composition: composed of bridge frame, lifting mechanism, trolley running mechanism, trolley running mechanism, and electrical system.

■ European technology, modular design, light weight, small wheel pressure, safe and reliable, green concept leads innovation, saves space and energy.

■ European standard design, crane height is reduced by 20-30%, reducing plant height and plant construction costs. The compact crane structure maximizes the use of working space.

■ Full frequency conversion control, the walking mechanism and lifting mechanism adopt three-in-one motor reducer, which runs smoothly, safely and reliably.

■ High working efficiency, the working level can reach A3-A7.

■ Customizable according to specific application requirements.

■ Lighter weight, lower wheel pressure, lower energy consumption.

■ Standardized, universal and serialized parts.

Main beam mechanism: generally adopts square box beam design, and the main welds are non-destructively tested to ensure welding quality. All steel plates are shot blasted to Sa2.5 standardization. The steel plates will be carefully inspected and cleaned before welding, and are usually welded by automatic welding machines. The steel plate material is Q235B. Q355B and Q355E low temperature resistant plates are suitable for use in minus 40° environments.

End beam mechanism: It is welded and formed by rectangular steel pipes or steel plates. After the end beam is welded, it is processed in one go on a CNC boring and milling machine to ensure dimensional accuracy and matching tolerance. The main beam and the end beam are connected with high-strength bolts and positioned with locating pins to ensure the accuracy of the whole machine and smooth operation.

Wheel mechanism: Double-ring wheels are used. The wheel is made of 40Cr or 42CrMo alloy steel, QT600, 65Mu and other materials, and is tempered as a whole, with high hardness, wear resistance and long service life.

The wheel bearing is a self-aligning bearing. When the bearing is subjected to an eccentric load, the roller will automatically adjust its position so that the bearing always keeps in contact with the axis, thereby improving the stability of the equipment operation.

Hoisting mechanism

Motor: A three-phase asynchronous variable frequency motor is usually used to provide the power source. The variable frequency motor can achieve stepless speed regulation to meet different lifting speed requirements.

Reducer: The motor is decelerated and the torque is increased by the industrial hard tooth surface reducer.

Drum: A cylindrical cylinder with a spiral groove on the surface, which is used to wind the wire rope, and the wire rope is retracted and released by forward and reverse rotation.

Wire rope: 8*26-2160 high-strength galvanized wire rope is used, which is wound on the drum, one end is fixed on the drum, and the other end is connected to the hook or sling to carry the weight of heavy objects.

Pulley block: The material is divided into high-strength nylon or Q235 material. The pulley block consists of a fixed pulley (fixed on the frame) and a movable pulley (connected to the hook). The lifting force is decelerated according to the reduction ratio (2, 4, 6, 8, 12) to improve the lifting capacity.

Brake: Electromagnetic brake or hydraulic brake is adopted. When the power is off, the brake wheel is automatically clamped to prevent the heavy object from falling; when the power is on, the brake is released to allow lifting.

Operating mechanism: The three-in-one drive system of motor, reducer and brake is adopted, which has compact structure, high transmission efficiency, stable operation, reliable braking and simple maintenance. Realize three-in-one drive to improve the safety and reliability of the equipment. The motor adopts a three-phase AC variable frequency motor. The reducer adopts a hard tooth surface reducer. The brake adopts an electromagnetic brake, and asbestos-free brake pads and brake discs are adopted.

Electrical system: Cranes often use variable frequency speed regulation technology. The inverter can change the frequency of the output power supply according to the instructions of the PLC (Programmable Logic Controller), thereby adjusting the speed of the motor. The layout design of the control box is reasonable, easy to maintain, and the protection level is IP54.

Crane power supply system: The following methods are adopted: 1. Seamless safety busbar 2. Tubular busbar 3. Single-machine H series safety busbar 4. Steel conductor busbar 5. Cable drum 6. Lithium battery power supply. Different power supply systems are adopted according to different use environments.

Crane operating system: 1. The cab has a wide field of vision, linkage control, easy operation, and better vision. 2. The wireless remote control control adopts a two-speed button or a four-speed remote control operation, which is stable and accurate, can realize remote control, easy operation, protection level IP65, and service life of 500,000 times. 3. The wired handle can resist interference and has the advantages of long service life.

Protective device:

1. Equipped with protective cover and guardrail to prevent the hook from hitting the top device.

2. The lifting mechanism is equipped with a height limiter. When the hook rises to the preset limit height, the limiter is triggered and the power supply of the lifting motor is immediately cut off, so that the hook stops rising and prevents the hook from hitting the top.

3. Overload protection is equipped with a high-precision overload limiter to monitor the lifting weight of the crane in real time. Once the lifting weight exceeds the set proportion of the rated lifting weight (usually 105% - 110%) , the overload limiter will quickly send out an audible and visual alarm signal, and automatically cut off the lifting power circuit, prohibiting the crane from continuing the lifting operation.

4. Travel limit protection "Both the trolley and the car operating mechanism are equipped with a travel limit switch. When the trolley or the car runs to the limit position at both ends of the track, the limit switch is triggered, and the power supply of the running motor is immediately cut off, so that the crane stops running, avoiding the crane from running off the track and causing derailment, falling and other dangers.

Electrical protection

Short circuit protection: Through devices such as fuses and circuit breakers, when a short circuit occurs in the circuit, the circuit is quickly cut off to prevent electrical equipment from being damaged due to excessive short-circuit current, and to avoid safety accidents such as fire.

Overload protection: Overload protection components such as thermal relays monitor the motor current in real time. When the motor is overloaded and the current exceeds the rated value, the thermal relay The electrical appliances are activated to cut off the power supply to the motor to prevent the motor from burning due to overheating.

Grounding protection: The metal structure of the crane, the casing of the electrical equipment, etc. are all reliably grounded. Once a leakage fault occurs in the equipment, the current can be introduced into the earth through the grounding wire to avoid electric shock accidents.

The sound and light alarm will promptly send out eye-catching warning signals in each operation link of the crane, such as starting, running, lifting, and descending. When the crane starts, the alarm will continue to emit a high-decibel whistle and flashing lights to remind people in the surrounding dangerous areas to evacuate quickly or be vigilant.

Application scenarios of electric double-beam bridge cranes: construction industry, industrial and mining workshops, machinery manufacturing workshops, metallurgical workshops, petroleum and petrochemical, railways, civil aviation, power stations, papermaking, building materials, electronics and other industries, factories and warehouses, etc.

Optional brands

■ Motor reducer: SEW, ABM, Nord, Siemens.

■ Electrical components: Schneider, Siemens, ABB, Honeywell

■ Inverter: Schneider, Siemens, ABB, Danfoss, Yaskawa

■ Bearing: SKF, NSK

■ Remote control: Taiwan Yuding, Apollo, HBC