Technical Parameter of MATE-MH M5 Single-Girder Gantry Crane | ||

| Rated Load | T | 1~20 |

| Work Level | M5 | |

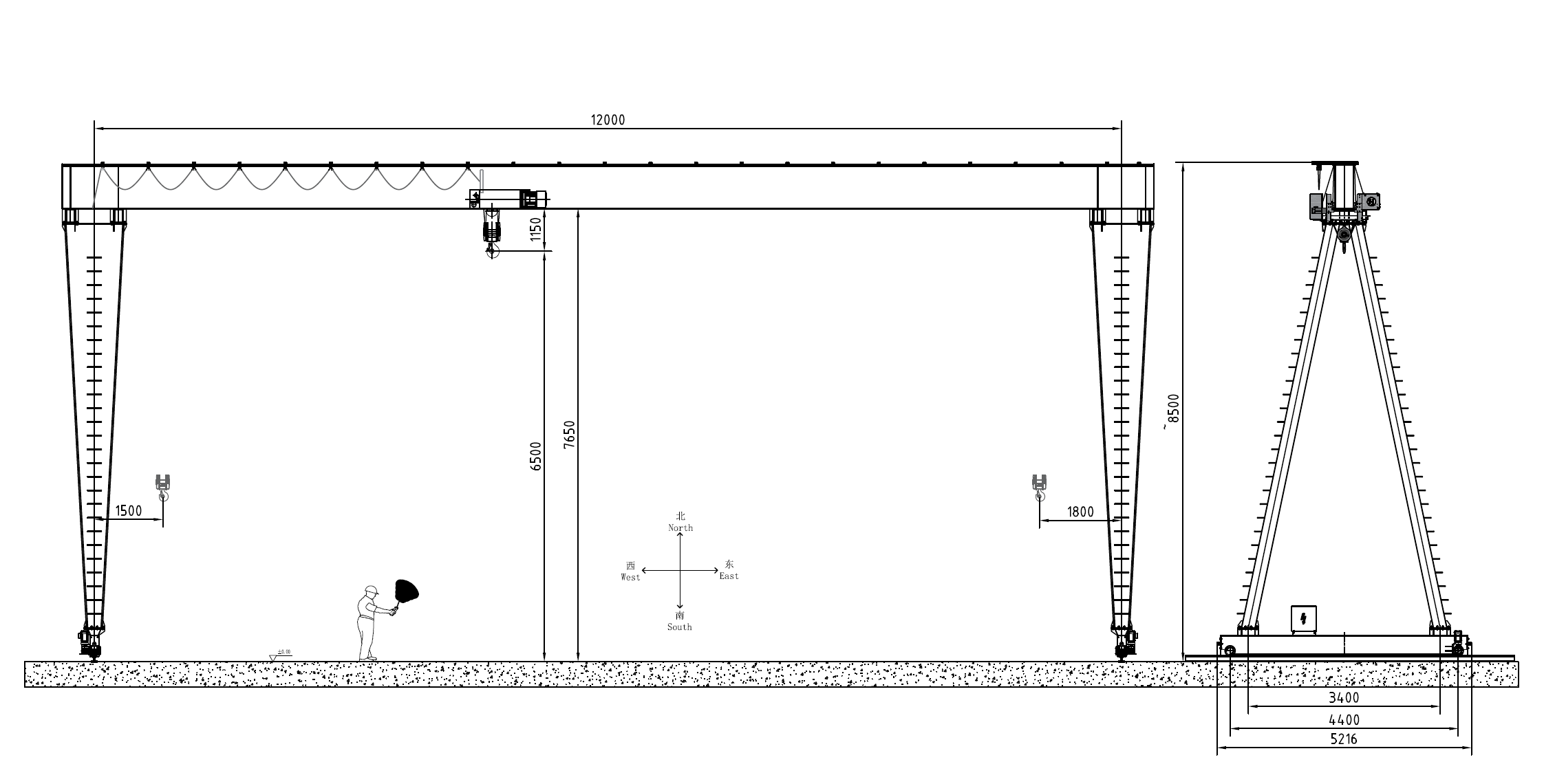

| Equipment Span | S(m) | 5~40 |

| Lifting Height | m | 6~30 |

| Product Certification | ISO, CE | |

| Design Standard | GB3811 | |

European single-beam gantry crane is designed and manufactured according to European standards, with advantages such as stable operation mechanism, low noise and maintenance-free.

The products are widely used in: various workshops and warehouses with low clearance but large lifting height, such as parts manufacturing workshops, automobile manufacturing, mechanical processing, warehouses, transfer equipment, heavy material transfer, etc.

■ Modular design,

■ Light weight, small wheel pressure, compact steel structure design

■ Variable frequency speed regulation, stable operation and low noise.

■ Less maintenance, saving maintenance costs.

■ The end beam is welded with rectangular tubes and processed by boring and milling machines.

■ The main beam and end beam can be easily and quickly assembled with bolts and nuts.

■ The crane is a low-headroom type, and the hook can be lifted higher.

■ Adopt box beam, submerged arc automatic welding, non-destructive testing, in line with EU standards.

■ High-quality carbon steel Q235B or Q355B or Q355E is used.

■ The operating mechanism adopts a three-in-one drive system, with motor, reducer and brake as one, small size, high transmission efficiency, maintenance-free and other advantages.

■ The motor adopts a three-phase AC variable frequency motor.

■ The reducer adopts a hardened gear reducer.

■ The brake adopts an electromagnetic brake, and uses asbestos-free brake pads and brake discs.

■ The wheel is made of 40Cr or 42CrMo alloy steel or QT500, 65Mn, and is tempered as a whole, with high hardness, wear resistance and long life.

■ It has the characteristics of high hardness, strong bearing capacity, wear resistance and long life.

■ The bearing adopts a self-aligning bearing.

■ The crane operating mechanism adopts inverter control, the speed can be adjusted, slow acceleration, smooth operation, etc.

■ High protection level, up to IP54.

■ Equipped with protective cover and guardrail to prevent the hook from hitting the top device.

■ Equipped with circuit self-check protection device

■ When the crane is placed outdoors, the lifting mechanism and the electric control box are equipped with rainproof devices

■ Equipped with anti-collision, sound and light alarm devices

■ Lifting weight limit, height limit

■ Motor reducer: SEW, ABM, Nord, Siemens

■ Electrical components: Schneider, Siemens, ABB, Honeywell

■ Inverter: Schneider, Siemens, ABB, Danfoss, Yaskawa

■ Bearings: SKF, NSK

■ Remote control: Taiwan Yuding, Apollo, HBC

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t |

| Span | 7-30m | ||||||

| Lifting height | 6-12m | 9-12m | |||||

| Work Duty | |||||||

| Lifting Speed | 0.6/4 m/min | ||||||

| Hoist Traveling speed | |||||||

| Crane Traveling Speed | |||||||

| Rail | P24 | P30 | P43 | ||||